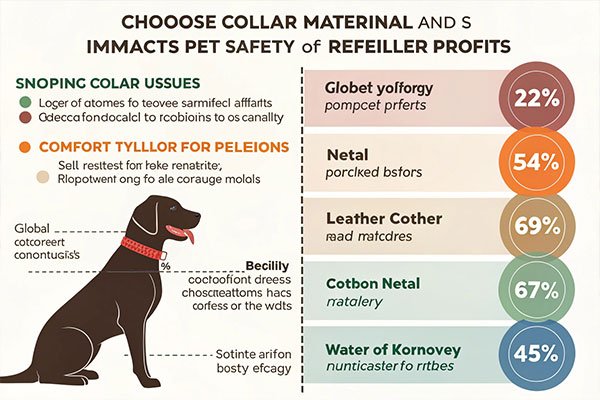

Choosing collar material impacts pet safety and retailer profits. Comfort issues cause costly returns. As global manufacturers, we simplify material decisions.

Nylon, leather, metal, polyester, and cotton serve different needs. Match to breed traits and lifestyle. Water dogs need waterproof options. Allergy-prone pets require hypoallergenic fabrics. Durability varies significantly by material type.

Smart material selection streamlines inventory and protects pets. Explore our professional comparisons.

What Are Common Materials for Dog Collars?

Retailers struggle with inferior materials that crack or irritate skin. Quality matters for consumer loyalty.

Leather, nylon, metal chains, polyester webbing, and cotton dominate the market. Each offers unique benefits. Leather develops character over time. Nylon survives vigorous play. Metal trains persistent pullers. Polyester maintains vivid colors. Cotton provides breathable comfort.

Material Specifications for Bulk Purchasers

| Material | Optimal Use Case | Durability Concern | Key Manufacturing Note |

|---|---|---|---|

| Leather | Premium markets | Cracking in dry climates | Use vegetable-tanned hides |

| Nylon | Active lifestyles | UV fading | Add extra UV coating |

| Metal | Training collars | Weight distribution | Laser-welded links required |

| Polyester | Vibrant color designs | Stretch limitations | Triple-dyed yarn process |

| Cotton | Sensitive skin pets | Moisture absorption | Pre-shrink during production |

Leather suits high-end brands with conditioning requirements. Nylon provides best value for volume orders. Metal chains require precision engineering to prevent pinching. Polyester holds colors longer than nylon. Cotton demands specialized treatments for longevity.

Leather

Leather collars gain patina but improper care causes cracks and returns. Humidity fluctuations accelerate deterioration.

Top-grain leather lasts 5+ years with maintenance. Full-grain performs best. Bonded leather fails quickly. Vegetable-tanning prevents allergic reactions. Monthly conditioning is non-negotiable.

Critical Manufacturing Parameters:

- Thickness Standards:

- 1.0-1.3mm (Small breeds)

- 1.4-1.8mm (Medium breeds)

- 2.0mm+ (Large/strong breeds)

- Durability Features:

- Chrome-free for chewers

- Reinforced stress points (6 stitches/inch)

- Buckle thickness matching leather weight

- Waterproof surface treatment

Provide buyers with care instructions. Offer conditioned samples for quality verification.

Nylon

Nylon dominates mass-market but poorly finished edges scratch skin. Quality starts with yarn selection.

Durable against mud and water. Denier ratings dictate strength: 1000D for large breeds, 600D for companions. Stress points require double-stitching and bar-tacking reinforcement.

Performance Specifications

| Weave Type | Ideal Application | Break Strength |

|---|---|---|

| Flat Weave | Basic collars | 200 lbs |

| Tubular | Adjustable fits | 350 lbs |

| Reflective | Low-light safety | 150 lbs |

Anti-microbial treatments prevent odor buildup. Verify UV-resistant coatings during sourcing.

Metal

Training collars demand precision manufacturing to prevent injuries. Substandard welding causes snagging.

Stainless steel provides optimal strength-to-weight ratio. Padded sleeves prevent fur damage, while zinc alloys are strictly avoided due to fast corrosion.

Manufacturing Quality Checklist:

- Material: Surgical-grade stainless steel

- Link thickness: Minimum 3mm for heavy breeds

- Welding method: Laser > spot welding

- Surface finish: Electropolishing eliminates burrs

- Consistency: ±2mm sizing tolerance

Test each batch for sharp edges during quality control inspection.

Polyester

Polyester excels in color retention but poor dyeing processes cause fading and bleeding. Production techniques matter.

Holds vibrant hues longer than nylon. Limited stretch reduces sagging. Solution-dyed yarns prevent wash fading. UV barriers maintain color integrity.

Color Performance Standards

| Property | Standard Grade | Premium Grade |

|---|---|---|

| Fade Resistance | 20 washes | 70+ washes |

| Color Options | Basic palette | Custom Pantone |

| Production MOQ | Volume-driven | Flexible |

Ideal for seasonal collections and branded merchandise. Request lab dip approvals before bulk orders.

Cotton

Organic cotton surges in popularity but untreated fabrics stain irreversibly and harbor bacteria. Specialized treatments solve this.

Breathable comfort prevents skin irritation. Moisture absorption requires countermeasures. Machine-washable constructions extend lifespan significantly.

Production Innovations:

- Hypoallergenic certification options

- Moisture-wicking nano-coatings

- Reinforced polyester cores

- Pre-shrunk processing prevents sizing issues

- Width minimum 1.5" for safety

Recommend double-layer designs for chewers. Provide washing instructions prominently.

How Do You Select the Right Material?

Material mismatches lead to unsatisfied customers and excess inventory. Breed-specific considerations prevent this.

Categorize by activity level and physical traits. Climate dictates material suitability. Our factory uses breed matrices to match materials.

Professional Selection Framework

1. Breed Analysis System:

- Bulldogs/Pugs: Wide nylon/polyester + quick-release

- Sled Dogs: Reinforced biothane + martingale closure

- Hunting Breeds: Reflective nylon + anti-slip webbing

- Puppies: Chew-resistant biothane only

2. Regional Adaptation:

- Tropical: Mold-proof materials

- Desert: UV-enhanced protection

- Urban: Reflectivity requirements

- Coastal: Saltwater-resistant finishes

3. Scaling Considerations:

- 60% core materials (nylon/polyester)

- 25% specialty (leather/biothane)

- 15% seasonal/variants

Request custom breed matrices for your target markets.

How Should Different Collars Be Maintained?

Improper cleaning damages integrity while bacteria buildup threatens pet health. Detailed protocols prevent both.

Material-specific methods preserve function. We embed visual washing instructions on every item. Intensive care routines double lifespan.

Comprehensive Care Protocols

Leather Collar Maintenance:

- Weekly: Wipe with damp microfiber cloth

- Monthly: Apply pH-balanced leather conditioner

- Deep Cleaning:

- Mix 1:4 distilled water to white vinegar

- Test on hidden spot before full application

- Blot (never scrub) with sponge

- Drying: Air dry away from heat sources

- Storage: Roll loosely in breathable cloth

Nylon/Polyester Care System:

- Pre-treatment: Brush embedded dirt with soft brush

- Machine Washing:

- Close buckles to prevent snagging

- Cold water only (under 30°C/86°F)

- Mild detergent without bleach

- Drying: Hang vertically in shade

- Periodic Treatment: Vinegar rinse for deodorizing

Metal Collar Preservation:

- Weekly: Inspect for frayed joints/edges

- Monthly:

- Soak in vinegar-water solution (1:3)

- Use soft toothbrush in crevices

- Rinse thoroughly

- Critical Component Care:

- Hinges: Food-grade mineral oil drops

- Pivots: Remove dirt with compressed air

- Preventive Measure: Store dry with silica gel

Cotton & Fabric Care:

- Post-Walk: Shake out debris immediately

- Washing:

- Pre-soak heavily soiled items

- Hot water wash (50°C/122°F maximum)

- Gentle cycle preferred

- Stain Removal:

- Baking soda paste for grease

- Hydrogen peroxide for organic stains

- Fabric Revival: Fabric softener wash quarterly

Always air dry completely before reuse. Never use dryer heat on any collar material.

Material selection requires professional insights. We produce reliable, customizable collars meeting global standards. Request our technical specifications package.